Table of Contents

spWall, developed by StructurePoint, stands as a cornerstone in structural engineering software, offering a robust platform for the design and analysis of concrete walls. This overview delves into the core features and functionalities of spWall, shedding light on its significance in modern engineering practice.

Introduction to spell 10.00

The design and engineering of industrial components demand meticulous attention to detail, with one of the fundamental aspects being the determination of wall thickness. Known as spell 10.00 in engineering terminology, this parameter is pivotal in ensuring structural integrity, performance, and longevity across diverse applications. From the automotive sector to aerospace, construction to manufacturing, the significance of spell 10.00 permeates various industries, influencing the design and fabrication processes of critical components.

Importance of spell 10.00

The importance of spell 10.00, or the specified wall thickness of 10.00 inches in engineering design, cannot be overstated, as it serves as a foundational element in ensuring the structural integrity, performance, and safety of industrial components. Several vital reasons underscore its significance:

- Structural Integrity: The specified wall thickness directly influences the structural integrity of components, providing the necessary strength and stability to withstand various loads and environmental conditions. In applications ranging from building structures to vehicle frames, adequate wall thickness is essential to prevent deformation, buckling, or failure under stress.

- Load Bearing Capacity: spWall 10.00 plays a crucial role in determining the load-bearing capacity of components, ensuring they can support the anticipated loads without experiencing excessive deflection or deformation. Whether a bridge supporting vehicular traffic or a pressure vessel containing fluids under high pressure, the specified wall thickness directly affects the component’s ability to carry applied loads safely.

- Durability and Longevity: Components with sufficient wall thickness are more durable and have a longer service life, as they are less prone to fatigue, corrosion, and other forms of degradation. By providing adequate material strength and protection against external factors, spWall 10.00 contributes to the longevity and reliability of industrial structures and equipment.

- Safety Considerations: In many applications, such as aerospace, automotive, and oil and gas industries, safety is paramount. The specified wall thickness ensures that components can withstand operating conditions and unforeseen events without compromising the safety of personnel or the public. This is particularly critical in pressure vessels, pipelines, and structural elements subjected to harsh environments or high-risk conditions.

- Material Efficiency: While ensuring structural robustness, spWall 10.00 also aims to optimize material usage, balancing performance and cost-effectiveness. By specifying an appropriate wall thickness, engineers can minimize material wastage while still meeting design requirements, enhancing efficiency, and reducing production costs.

- Regulatory Compliance: Many industries are subject to regulatory standards and codes that mandate minimum wall thickness requirements for specific components. Compliance with these regulations is essential to ensure industrial installations’ safety, reliability, and legal compliance. Spell 10.00 ensures adherence to such standards, safeguarding against potential liabilities and penalties.

- Manufacturability: The specified wall thickness also considers manufacturability aspects, such as machining, casting, welding, or additive manufacturing processes. By selecting an optimal wall thickness, engineers can facilitate easier fabrication and assembly while minimizing production complexities and costs.

StructurePoint spWall Overview

StructurePoint’s SPWall is a specialized software solution crafted for the intricate task of designing and analyzing retaining walls, particularly within the realm of civil engineering and construction. Tailored to meet the needs of engineers and architects involved in planning and executing retaining structures, SPWall is an indispensable tool, offering a rich array of features and capabilities essential for ensuring stability, safety, and efficiency in critical projects.

Key Features:

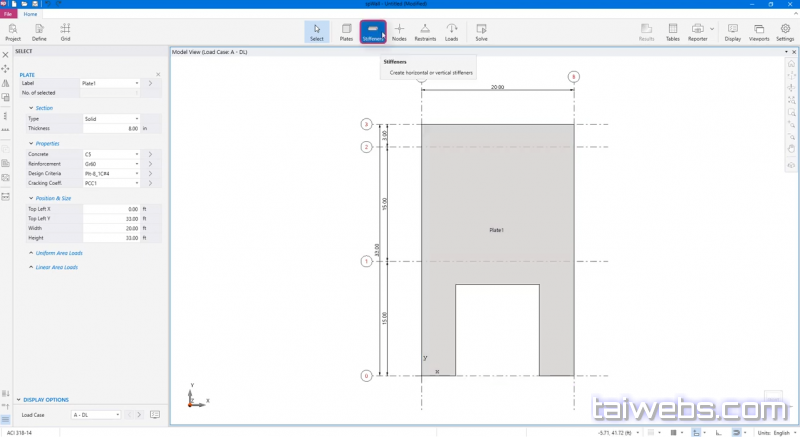

Comprehensive Design Capabilities: spWall facilitates the design and analysis of various concrete wall types, including reinforced concrete, tilt-up, ICF, and precast panels.

- Intuitive Graphical Interface: Users benefit from a user-friendly graphical interface that simplifies the generation of complex wall models.

- Customizable Parameters: From wall geometry to material properties, users can tailor design parameters to meet project-specific requirements.

- Load Analysis: spWall enables the graphical assignment of loads, including point, line, and area loads, ensuring accurate structural analysis.

- Support Conditions: Users can define support conditions graphically, enhancing the precision of structural simulations.

- Spring Assignment: The software allows for the graphical assignment of translational and rotational springs at any node, facilitating advanced analysis.

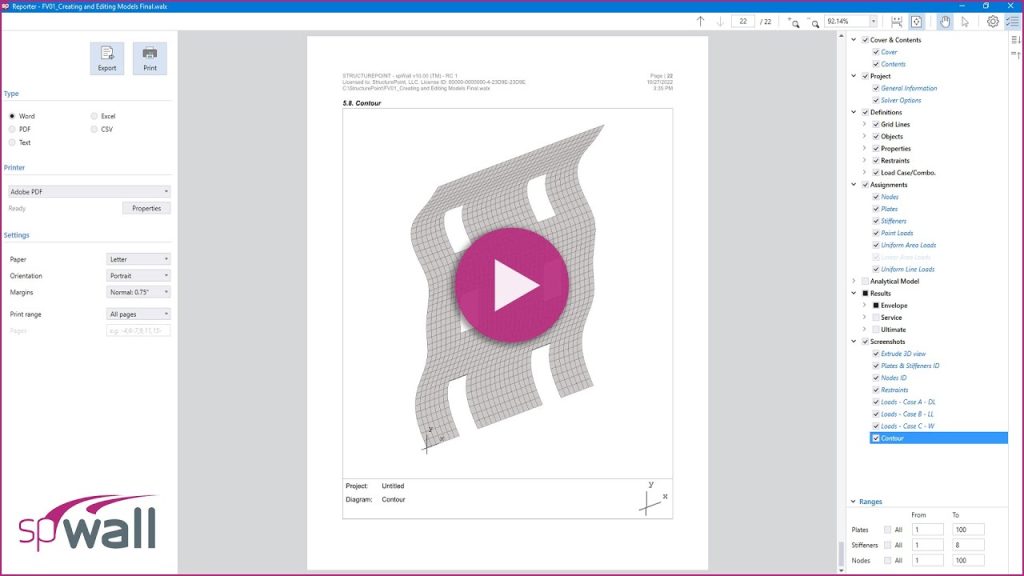

- Integration Capabilities: spWall seamlessly integrates with other software tools and platforms, ensuring compatibility and workflow efficiency.

What is the latest version of StructurePoint spell?

The project undergoes regular updates by its developers, ensuring users benefit from the latest enhancements and features. Visit the developers’ official website to access the most recent software update.

Frequently Asked Questions

What is the importance of a small 10.00 in structural engineering?

spWall 10.00 plays a crucial role in structural engineering by providing a comprehensive platform for designing and analyzing various types of concrete walls. Its advanced features and intuitive interface contribute to efficient and accurate structural design.

What factors influence the usage of the spell 10.00?

Several factors influence the usage of spell 10.00, including its user interface, accuracy, flexibility in design parameters, integration capabilities with other tools, and the availability of technical support and updates.

How can a small 10.00 be optimized for better performance?

Optimization strategies for spWall 10.00 include techniques such as parameter optimization (optimizing wall geometry, material properties, and load analysis), performance optimization (enhancing computational efficiency and reducing errors), integration and collaboration optimization (integrating with BIM and CAD platforms, facilitating collaborative workflows), and continuous improvement strategies (incorporating user feedback and investing in research and development).

Conclusion

spWall 10.00 plays a vital role in engineering design, offering a cornerstone for ensuring structural integrity, performance, and safety across diverse industrial applications. Through our exploration of its importance, factors influencing its determination, and optimization